Building a fuel vaporizer

Warning!

Some activities described on this site are dangerous and could result in injury or death. We, and anyone affiliated with this site, do not encourage these types of activities. If you choose to take part in any of these activities, you do so entirely at you own risk. We will not be held responsible for any and all claims resulting from your actions. Reading any parts of this site indicates that you accept these terms.

Some activities described on this site are dangerous and could result in injury or death. We, and anyone affiliated with this site, do not encourage these types of activities. If you choose to take part in any of these activities, you do so entirely at you own risk. We will not be held responsible for any and all claims resulting from your actions. Reading any parts of this site indicates that you accept these terms.

Gasoline poisons the atmosphere and is very toxic and dangerous.

Internal combustion engine and gasoline

It is often a misconception that internal combustion engines today burn gasoline vapours. In fact, gasoline powered vehicles burn fine particles or droplets which are sprayed from the carburetor or fuel injectors into the engine.

Most people don’t know that “internal combustion” is defined as a “thermo-vapour process”’ as in “no liquid in the reaction”. Why are we trying to burn liquid gasoline in an internal combustion engine? Only about 30% of the gasoline is burned in the cylinders. Of the small percentage which vaporizes and produces energy, about 70% is wasted as heat. The liquid gasoline that wasn’t burned in the cylinders is now hot enough to vaporize, consuming the oxygen, producing carbon monoxide, which cools off and comes out the tail pipe as smog.

The oil companies, auto manufacturers, government and other big corporations have convinced most of us that this is the way to go...burn lots of fuel and make the oil companies happy! Pollute lots and make the government happy, so they can then tax us to death. Buy new energy efficient cars…make auto companies happy! Because they are throw away cars. There is less pollution in repairing an older car than buying a new one. Why do they put catalytic converters on new vehicles if they are so energy efficient? The newer cars are more gas-guzzlers than the older ones. The smaller engines of today should get double the gas mileage than they do.

Gasoline is composed of many different hydrocarbons. When crude oil is refined, it goes through many different processes before it can be blended into gasoline. Some fuel is further processed through a unit to produce higher-octane fuel. Lower octane gasoline is the least processed.

Gasoline starts to vaporize at about 100F. In some areas where the temperature can reach over 100F in the summer gasoline is blended with other components. For example a summer blend may consist of 25% straight gasoline, 15% alkylate (like an octane booster) 40% FCC (fluid catalytic cracker) 18% reformate and 2% butane. While in the wintertime there may be 10% or so butane. In other words, the oil companies keep the vapour pressure down in the summer and a little higher in the winter so that engines are easy to start in the winter and so it does not boil in the summer and cause vapour lock.

Carburetors are nothing but an automatic fuel regulating system, that does not vaporize the fuel. Fuel injectors are not much better as they just produce a mist. Liquid fuel does not burn, you must vaporize any fuel in order for it to burn properly.

For every 20 gallons of gas you put into you tank only about 6 gallons will be burned up in your engine and the rest will build up in your engine as carbon. Some of it will be collected as unburned hydrocarbons by the catalytic converter, and the rest will come out the tail pipe as pollution.

We have to start thinking a little differently. Instead of the crude approach think of a smarter, cheaper way. Think of a tuning fork that can break a wine glass with little effort instead of smashing it with a hammer. Think “smart energy” not “crude energy”.

Why don’t we vaporise the fuel before it enters the cylinders, then the vapour will burn 100% and produce very little pollution, use less fuel, and get better performance, “smart energy”.

*1933-1936 Charles Nelson Pogue patented his vaporizer type carburetor and claimed 200 miles per gallon. He sold a few carburetors, but, all of a sudden, no more carburetors and he becomes a wealthy owner of a filter company. Pogue Carbs were installed in some U.S. tanks and jeeps in Africa, during WWII. It was also during this time period that lead was introduced to gasoline, which was one way to screw up the vaporizer.

*About 1960 the Fish Carburetor went into production on a small scale. A couple of years later the Fish Carburetor faded away for some unknown reason.

*1968 The Ford Motor Company built an engine with a different type of combustion chamber with fuel injection. When tested on a 460 cid engine, it ran very well on a 26:1 fuel ratio. This engine was to go into production in 1985.

*In 1976 a Nissan diesel engine with a turbocharger is tested and gets 80 mpg.

*1978 The Flex Vaporizer claims to double your gas mileage up to 110 mpg.

Most people don’t know that “internal combustion” is defined as a “thermo-vapour process”’ as in “no liquid in the reaction”. Why are we trying to burn liquid gasoline in an internal combustion engine? Only about 30% of the gasoline is burned in the cylinders. Of the small percentage which vaporizes and produces energy, about 70% is wasted as heat. The liquid gasoline that wasn’t burned in the cylinders is now hot enough to vaporize, consuming the oxygen, producing carbon monoxide, which cools off and comes out the tail pipe as smog.

The oil companies, auto manufacturers, government and other big corporations have convinced most of us that this is the way to go...burn lots of fuel and make the oil companies happy! Pollute lots and make the government happy, so they can then tax us to death. Buy new energy efficient cars…make auto companies happy! Because they are throw away cars. There is less pollution in repairing an older car than buying a new one. Why do they put catalytic converters on new vehicles if they are so energy efficient? The newer cars are more gas-guzzlers than the older ones. The smaller engines of today should get double the gas mileage than they do.

Gasoline is composed of many different hydrocarbons. When crude oil is refined, it goes through many different processes before it can be blended into gasoline. Some fuel is further processed through a unit to produce higher-octane fuel. Lower octane gasoline is the least processed.

Gasoline starts to vaporize at about 100F. In some areas where the temperature can reach over 100F in the summer gasoline is blended with other components. For example a summer blend may consist of 25% straight gasoline, 15% alkylate (like an octane booster) 40% FCC (fluid catalytic cracker) 18% reformate and 2% butane. While in the wintertime there may be 10% or so butane. In other words, the oil companies keep the vapour pressure down in the summer and a little higher in the winter so that engines are easy to start in the winter and so it does not boil in the summer and cause vapour lock.

Carburetors are nothing but an automatic fuel regulating system, that does not vaporize the fuel. Fuel injectors are not much better as they just produce a mist. Liquid fuel does not burn, you must vaporize any fuel in order for it to burn properly.

For every 20 gallons of gas you put into you tank only about 6 gallons will be burned up in your engine and the rest will build up in your engine as carbon. Some of it will be collected as unburned hydrocarbons by the catalytic converter, and the rest will come out the tail pipe as pollution.

We have to start thinking a little differently. Instead of the crude approach think of a smarter, cheaper way. Think of a tuning fork that can break a wine glass with little effort instead of smashing it with a hammer. Think “smart energy” not “crude energy”.

Why don’t we vaporise the fuel before it enters the cylinders, then the vapour will burn 100% and produce very little pollution, use less fuel, and get better performance, “smart energy”.

*1933-1936 Charles Nelson Pogue patented his vaporizer type carburetor and claimed 200 miles per gallon. He sold a few carburetors, but, all of a sudden, no more carburetors and he becomes a wealthy owner of a filter company. Pogue Carbs were installed in some U.S. tanks and jeeps in Africa, during WWII. It was also during this time period that lead was introduced to gasoline, which was one way to screw up the vaporizer.

*About 1960 the Fish Carburetor went into production on a small scale. A couple of years later the Fish Carburetor faded away for some unknown reason.

*1968 The Ford Motor Company built an engine with a different type of combustion chamber with fuel injection. When tested on a 460 cid engine, it ran very well on a 26:1 fuel ratio. This engine was to go into production in 1985.

*In 1976 a Nissan diesel engine with a turbocharger is tested and gets 80 mpg.

*1978 The Flex Vaporizer claims to double your gas mileage up to 110 mpg.

These are just a few of the hundreds of inventions that I’ve mentioned. The unusual thing about this is that this information is available to anyone who wants to take the time to search. So why aren’t more people driving cars with better mileage? Well the auto companies tell us that the regular carburetor is very efficient at a fuel ratio of 15:1. I found out that an ordinary engine would run quite well on a ratio of way over 50:1.

All the inventors of the high mileage carburetors have the right idea. Liquid fuel must be vaporized before being mixed with incoming air to be burned efficiently; otherwise the liquid fuel goes right through the engine into the air as pollution. Propane and butane engines do not have a liquid carburetor, because the liquid is vaporized before it enters the engine. The pollution in propane engines is minimal, thus no need for catalytic converters. Did anyone notice that our so-called fuel-efficient cars of today still have catalytic converters!!

It all depends on the grade of fuel and which fuel you are using (winter fuel or summer fuel) for the vaporizer. As high-grade winter fuel will vaporize sooner than lower grade summer fuel. I have also noticed that in my "Vaparator", the gasoline itself will vaporize and you will be left with gummy, gooey stuff, which are all the additives. My understanding is that you need to heat the fuel a lot higher in order for everything to vaporize.

All the inventors of the high mileage carburetors have the right idea. Liquid fuel must be vaporized before being mixed with incoming air to be burned efficiently; otherwise the liquid fuel goes right through the engine into the air as pollution. Propane and butane engines do not have a liquid carburetor, because the liquid is vaporized before it enters the engine. The pollution in propane engines is minimal, thus no need for catalytic converters. Did anyone notice that our so-called fuel-efficient cars of today still have catalytic converters!!

It all depends on the grade of fuel and which fuel you are using (winter fuel or summer fuel) for the vaporizer. As high-grade winter fuel will vaporize sooner than lower grade summer fuel. I have also noticed that in my "Vaparator", the gasoline itself will vaporize and you will be left with gummy, gooey stuff, which are all the additives. My understanding is that you need to heat the fuel a lot higher in order for everything to vaporize.

Fuel Vaporizer V1

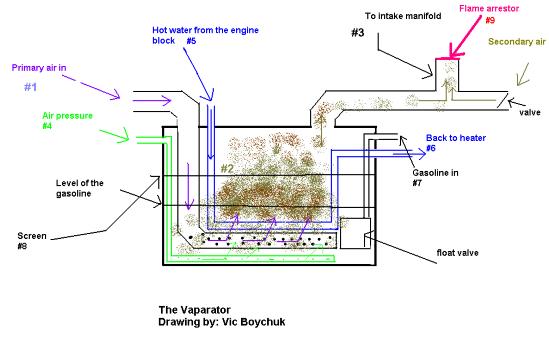

Here is a diagram of my home made vaporizer

Not drawn to scale

The Vaparator

#1 The air enters this 2” PVC tube, goes down through the gasoline. Here the tube has many small holes drilled at the bottom. The air comes out of these holes into the gasoline and produces a lot of small bubbles. The smaller the holes, the smaller the bubbles, the finer the vapour.

#2 The fine vapour is then sucked up to #3, mixed with the right amount of air, then goes to the intake manifold and into the cylinders.

#4 I also installed a smaller tube that went to the bottom of the fuel. The line is blocked off at one end, and I drilled more tiny holes at the bottom. I added a little air pressure to this tube, which produced more vapour.

#5 This copper tubing carried the hot water from the engine and back to the heater #6. This is my heat exchanger to keep the fuel hot.

#7 The fuel enters here and goes to a float valve I made from an old carburetor. This keeps the level of the gasoline the same all the time.

#8 I made a screen with some scratch pads about 2” above the fuel level so the liquid fuel does not enter the engine.

#9 Last, but the most important, the flame arrestor is a must, in order to prevent a flash back from the engine. I made my flame arrestor from a couple of screens from a screen door. Steel screen not plastic.

In conjunction with the Vaparator, I have a water vaporizer (to introduce small amounts of water vapour) and my Booster Juce (hydrogen cell)

#2 The fine vapour is then sucked up to #3, mixed with the right amount of air, then goes to the intake manifold and into the cylinders.

#4 I also installed a smaller tube that went to the bottom of the fuel. The line is blocked off at one end, and I drilled more tiny holes at the bottom. I added a little air pressure to this tube, which produced more vapour.

#5 This copper tubing carried the hot water from the engine and back to the heater #6. This is my heat exchanger to keep the fuel hot.

#7 The fuel enters here and goes to a float valve I made from an old carburetor. This keeps the level of the gasoline the same all the time.

#8 I made a screen with some scratch pads about 2” above the fuel level so the liquid fuel does not enter the engine.

#9 Last, but the most important, the flame arrestor is a must, in order to prevent a flash back from the engine. I made my flame arrestor from a couple of screens from a screen door. Steel screen not plastic.

In conjunction with the Vaparator, I have a water vaporizer (to introduce small amounts of water vapour) and my Booster Juce (hydrogen cell)

Here are some of my results after testing the vaporizer

*The level of the fuel in the Vaparator has to be just right, in order for the engine to run smoothly.

*The float valve does not work properly due to all the bubbling of the gasoline.

*The temperature of the fuel has to be a lot hotter in order for all the fuel and additives to vaporize.

*The small tube (#4) is not needed. The vacuum of the engine is more than enough.

*The first few tests I ran the Vaparator only, then I did a few more tests, with the fuel vaporizer, booster juce, and water vaporizer. The results were very close to 50 miles per gallon, on a 1986 Ford Ranger with V6.

Overall I am impressed with the way the Vaparator performed. It does need a lot of modification, but being the first one I built it worked better that I expected.

*The float valve does not work properly due to all the bubbling of the gasoline.

*The temperature of the fuel has to be a lot hotter in order for all the fuel and additives to vaporize.

*The small tube (#4) is not needed. The vacuum of the engine is more than enough.

*The first few tests I ran the Vaparator only, then I did a few more tests, with the fuel vaporizer, booster juce, and water vaporizer. The results were very close to 50 miles per gallon, on a 1986 Ford Ranger with V6.

Overall I am impressed with the way the Vaparator performed. It does need a lot of modification, but being the first one I built it worked better that I expected.

This is what is left after running the vaporizer. The additives did not vaporize.

Her is a video on how I built my vaporizer V1

Holes in PVC to vaporize fuel

Float valve

Our Vimeo Channel: The Goldseekers

Our U Tube Channel: TheGoldseekers